Knife Sharpening and Repair

Twice As Sharp For Twice As Long!

Knife repairs on low speed machines prevents the steel from overheating (and softening). Repairs may include:

- Repairing broken tips

- Removing chips from edges

- Straightening dips ("swales") from edges

- Grinding down finger guards ("bolsters") so knife edges rest flat on cutting boards

- Ergonomically rounding off top edge

The key to knife repairs, especially to expensive Japanese knives such as Global, Miyabi, and Shun is a variable-speed machine. I built such a machine as none was commercially available. This means grinding away as little steel as possible while preserving the hardness of the steel that you paid a lot of money for!

Machines calibrated to within 1/10 of a mm means edges twice as sharp as factory. Your benefit: edges stay sharp for at least twice as long!

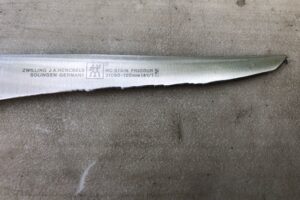

Some knife repair pictures below: